U.S. Senator Jon Ossoff from Georgia recently introduced the Solar Energy Manufacturing for America Act to boost American solar manufacturing. The legislation is co-sponsored by Senators Reverend Raphael Warnock (D-GA), Michael Bennet (D-CO), and Debbie Stabenow (D-MI).

Sen. Ossoff hopes this legislation will boost the American solar industry to create American clean energy jobs, better compete with Chinese manufacturers, and support American energy independence. Although the language of the bill says it is for “solar manufacturing,” it is clear that this is for solar panel manufacturing specifically.

“We strongly support Senator Ossoff’s manufacturing proposal and commend his leadership on this critical topic,” said Abigail Ross Hopper, president and CEO of the Solar Energy Industries Association (SEIA). “This legislation is an important step for spurring domestic manufacturing across all key elements of the solar supply chain and we look forward to helping it advance through Congress. In support of Senator Ossoff’s proposal, we are today setting a target of 50 GW of annual domestic solar production capacity by 2030, including polysilicon, wafers, cells and modules, racking and trackers and inverters. It is time to seize the promise of American solar manufacturing.”

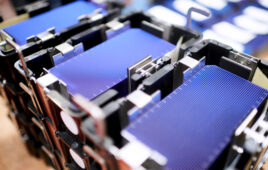

The Solar Energy Manufacturing for America Act would provide tax credits for American manufacturers at every stage of the solar panel manufacturing supply chain, from production of polysilicon to solar cells to fully assembled solar modules.

The suggested credits (which would begin in 2022) include:

- A solar panel would receive a 7-cent/watt credit

- An integrated module (assuming that means modules with microinverters or power optimziers pre-attached) would receive an 11-cent/watt credit

- PV cells would receive a 4-cent/watt credit

- Silicon wafers would receive a $12 per square meter credit

- Solar-grade polysilicon would receive a $3 per kilogram credit

The credits would begin to phase out to 70% in 2029 and 35% in 2030 before ending completely in 2031.

Unsurprisingly, this Act is supported by Q CELLS, which has a 1.7-GW solar panel manufacturing facility in Ossoff’s home state of Georgia.

“This is exactly the kind of policy the United States needs to scale the solar manufacturing sector and compete on the world stage. This proposal would create tens of thousands of good-paying manufacturing jobs across America in places like our home of Dalton, Georgia,” said Scott Moskowitz, Director of Market Intelligence and Public Affairs at Hanwha Q CELLS North America. “Further, the Solar Energy Manufacturing for America Act will help to diversify the entire solar supply chain, increasing the United States’ energy security while allowing us to competitively meet domestic and global solar energy demand. Solar is the future and Senators Ossoff, Warnock, Stabenow and Bennet are paving the way to help make Georgia and the United States a world leader in clean energy manufacturing. We look forward to working with him to turn this into law.”

The bill is also supported by Hemlock Semiconductors, LG Electronics USA, REC Silicon ASA, Wacker Polysilicon North America, Sunnova Energy International Inc., First Solar, Mission Solar, Leading Edge Equipment Technologies, Auxin Solar, Swift Solar, 1366 Technologies, Silfab Solar, Heliene, and the Ultra Low Carbon Solar Alliance.

Would the credits cover thin film PV printed on a substrate?

Everyone in the US solar industry should be supporting this bill.

A rising tide lifts all ships!

What about B.O.S components? Our company manufactures 100% in America, but are constantly faced with the same situation and Chinese price pressures the module supply chain has.

As of now, it looks like this would only be for those making solar panels/cells.

Where the Democrats five years ago when tariffs were smartly put in place on dumped solar modules along with lower corporate tax rates to incent domestic manufacturing?

And this same Senator is fine with increasing the corporate tax rate, then at same time provide a tax credit. Completely incongruent policy.

Of course this is his political favor for a manufacturer in his State. He might ask what brought Q Cells to Georgia in the first place. Maybe keeping the rate low will provide more of what got Q-Cells to his state.

Oil, gas, nuclear, and coal companies all got lower tax rates under the prior administration with the majority of these firms buying back their own stocks to pump management compensation and shareholder returns while laying off thousands of their workers. All while continuing to receive, as they have for the last 50 years, all manner of tax credits, grants and cost savings thru weakened environmental regulations. Completely incongruent policy is the American way.

Once again heading in the right direction with the tax credits and glad to see all the support. The fact that they are looking to reward solar panel supply chains that are “Made in America” shows the industry is making some great headway.

Hopefully one day, they also start to provide credits to solar companies who follow a certain guideline when it comes to installations and products.

“Sen. Ossoff hopes this legislation will boost the American solar industry to create American clean energy jobs, better compete with Chinese manufacturers, and support American energy independence. Although the language of the bill says it is for “solar manufacturing,” it is clear that this is for solar panel manufacturing specifically.”

One just needs to keep in mind, here in the U.S. the workforce will consist for the most part shipping and receiving actual employee bodies and even then parts, sub-assemblies and finished assemblies may all be automated, just like the manufacturing line from the standard crystal pull, to cutting into cells, doping the cells and assembling the cells into panels, will be for the most part automated.

“Unsurprisingly, this Act is supported by Q CELLS, which has a 1.7-GW solar panel manufacturing facility in Ossoff’s home state of Georgia.”

Unsurprisingly, just plain old ‘pork’ politics for the constituents to get more ‘votes’ next time around. These votes pork accounts are what ‘legacy’ politicians depend on in “off years”. This ‘kid’ Ossoff is new to Congress, but already is playing the game like a pro.

“In support of Senator Ossoff’s proposal, we are today setting a target of 50 GW of annual domestic solar production capacity by 2030, including polysilicon, wafers, cells and modules, racking and trackers and inverters. It is time to seize the promise of American solar manufacturing.”

The true leader in solar PV panel technology in the U.S., is the outlier CdTe thin film solar PV panels from First Solar. At 1.9GW yearly manufacturing capacity and still growing, the plan is to power their manufacturing lines with solar PV by 2028 and they have had a cradle to cradle panel recycling program in place since 2003. I believe with First Solar’s 22 years of experience in the thin film industry, they would be the best bet at bringing perovskites into the solar PV panel as a tandem element and perhaps get to the tipping point of tandem thin film panels with over 30% solar harvest efficiency and the ability to generate 80% or more electricity after 25 years of service.

“This proposal would create tens of thousands of good-paying manufacturing jobs across America in places like our home of Dalton, Georgia,” said Scott Moskowitz, Director of Market Intelligence and Public Affairs at Hanwha Q CELLS North America.”

Yeah, tens of thousands of good paying manufacturing jobs. AND compete with China’s already established capacity and well known practice to subsidize solar PV panel prices to sterilize the solar PV manufacturing business from many countries of the World.

You sound like a First Solar Sales rep.

I’m not in the utility scale solar PV market, where First Solar has decided to concentrate on 24 square foot solar PV panels that have panel outputs made for about 180VDC specifically for utility solar PV strings of 1,000 to 1,200VDC. First Solar has it’s very large niche market and needs no sales. As such it has been recently announced First Solar will increase factory output to around 3.3GW a year.

Would it be OK if I find their endeavors over the last 22 years as a company that chose thin film solar PV when the majority of the World was developing their own mono-silicon and poly-silicon solar PV cells. Over those years First Solar not only survived, but competed with China and their solar PV products where many others didn’t.