Manufacturers of mounting, racking and tracking components for solar systems have found that an “a la carte” approach to preparing the equipment for installers to assemble is more effective than providing an all-in-one, preassembled solution.

Preassembled racking might work in an installer’s favor in areas with notably high labor costs, where shortening install time is imperative. But large, ready-to-go racking solutions can take up more space than systems that require total or partial assembly, which can increase shipping prices for installers trying to keep costs down. Steve Daniel, executive VP of sales and marketing with Solar FlexRack, said the company still carries preassembled mounting and racking solutions, but they account for only about 5% of its sales.

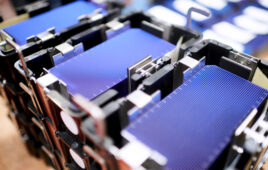

Solar FlexRack

“It’s more in process engineering and in training and really how well your install process is that’s driving the efficiencies,” he said.

Instead, Solar FlexRack has found assembling some portions of equipment before sending it to installers works well. Take the idler bearing in its TDP 2.0 solar tracker — the bearing requires fastening four separate pieces using two different types of bolts and nuts, but it’s small enough to transport the components as preassembled without sacrificing shipping space. Preassembling pieces of solar equipment that require extra attention to put together, but don’t take up much space, can be a benefit to installers.

Instead of requiring methods like welding, manufacturers are shifting assembly requirements toward hand tools and power drills. “Nothing that a normal person wouldn’t have in their tool bag,” Daniel said. Welding requires extra equipment, time and experienced personnel.

Above all, it’s important for installers to establish stronger working relationships with solar racking manufacturers to help improve install times.

“The installation community has become so much better,” Daniel said. “I mean, the cost of installation has gone down remarkably. What we try to do is we make sure we have the right services and right training up front to make sure they understand our products.”

Tell Us What You Think!