The inverter manufacturing market is always competitive, but the past year was even more challenging for companies. A Wood Mackenzie report found total revenue for the Top 5 global inverter vendors declined 10% last year due to price pressure and fierce competition. These issues caused numerous acquisitions and exits in 2019: ABB paid Fimer to take over its inverter business, Schneider Electric exited the utility-scale inverter business and KACO sold its string and central inverter businesses to Siemens and OCI Power, respectively.

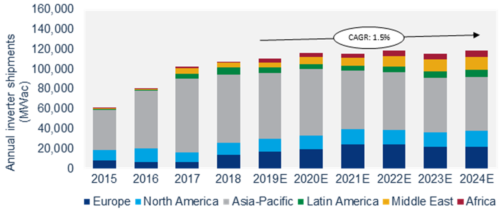

WoodMac found that even though global PV inverter shipments will continue to rise, market value will decline through 2024.

Many companies that have been able to hold on are focusing on diversifying their offerings by including comprehensive internet-of-things (IoT) platforms with inverters. For example, SolarEdge now provides whole-home solar + storage solutions, from power optimizers to EV chargers. All the pieces of the system can communicate through the company’s monitoring platform.

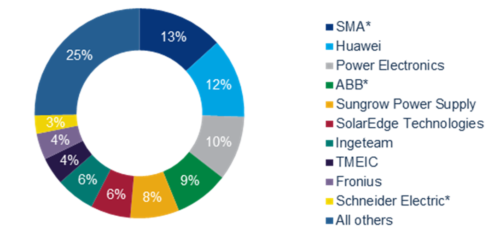

Top 10 inverter vendors by shipments, excluding China’s market (MWAC), 2018. Wood Mackenzie Power & Renewables

Enphase is also rolling out a whole-home, IoT-connected solution unlike any before. Its Ensemble system is capable of isolating from the grid in case of outages, with the ability to still power the home even without a battery when the sun is shining. Customers can also add batteries to have whole-home backup if the grid goes down at any time of day. Ensemble comes with Enlighten Cloud Software that’s responsible for monitoring the system.

Other companies, like APsystems and Schneider Electric, have released their own rapid shutdown devices to add another revenue stream and compete with Tigo Energy.

WoodMac’s study finds central and three-phase string inverters will see the sharpest drops in revenue of any product type from 2019 through 2024, but microinverters, single-phase string inverters, DC optimizers and hybrid inverters will instead experience growth in that time frame.

In addition to internal competition among inverter brands, tariffs have added more complexity to the market too. The Trump administration placed 25% tariffs on Chinese goods including inverters in May 2019. Chinese inverter manufacturers made costly adjustments to try to get around these tariffs, including moving manufacturing of U.S.-bound inverters to other countries. Sungrow, for example, took over a facility in Bangalore, India, with 3 GW of annual production capacity to produce all its American inverters.

Despite the challenges, the inverter section of Solar Power International 2019 was robust, with the surviving companies showcasing new products in flashy, expensive booth spaces. As inverter technology continues to advance, it will be interesting to watch which players stay strong and which are forced to make tough decisions like consolidating or exiting the market altogether.

Electricity through solar without reliance on grid or batteries will be a welcome advancement for providing clean energy for many schools ,institutions in remote areas ,looking forward for products like Ensemble

please take a look at Phocos.com. Anygrid.

SMA residential inverters have had the ability to provide power to the home in a daytime grid outage without batteries since 2013. Glad Enphase is finally joining the party!

i hope that the leading inverters building units will improve their brands in a way where the residents will be free of any governments provided facilities in power sectors and will be also low priced equipments .

Most Inverters being shipped to Africa has a tendency of failing within 1 to 2 years. How do you source the market for good quality inverters?

I’ve found the pull out of ABB from residential solar PV inverters interesting. Look at large inverter players like YASKAWA, a well known industrial VFD manufacturer for about 50 years. It seems like a lot of these old school inverter manufacturers find it difficult to supply the 60HZ, 240VAC or 50HZ, 230VAC residential inverters. Large solar PV farms and commercial sites still use 460/480 VAC in three phase designs, designs that have been used in the control of electric motor speeds with VFD technology.

Cree and other manufacturers are bringing along silicon carbide high temperature switching transistors into the market place. Demand in the market place will increase the manufacturing of such devices and decrease the cost of inverters who adopt this technology for their inverter product(s). Over those 50 years in the industry, the DSP, the control algorithms, and now the power driver of the output are pretty much standard within the inverter industry.

Right I hope prices keep going down.

Love it

Chinese companies will try to reduce the prices to get their share

I hope prices keep going down