A steel processing plant in Pennsylvania that predates World War I has returned to operations and is producing crucial components for an industry non-existent 100 years ago — solar power.

Bethlehem Steel was founded in 1904 in Leetsdale, Pennsylvania, a town about 20 miles northwest of Pittsburgh. The factory was dormant for years and still had dirt floors at the beginning of 2022. In June of this year, part of the interior was rebuilt to accommodate manufacturing lines for torque tubes — the rotating portion of a single-axis solar tracker — used in racking developed by Nextracker, one of the largest manufacturers of solar trackers on the planet.

A crane operator hauls completed torque tubes across the factory floor at Nextracker’s Leetsdale, Pennsylvania, factory. Billy Ludt/Solar Power World

“This has been an industrial place for a long time,” said Matt Carroll, CEO of BCI Steel, a longtime contract manufacturer running Nextracker’s new Pennsylvania factory. “All along this river were steel mills. Mill after mill after mill — most of that is gone. This factory is a rekindling of that industrial heritage.”

The next several years will undoubtedly be busy for solar manufacturing in the United States. The Inflation Reduction Act includes federal provisions for manufacturing tax credits to bolster and support new and existing production operations for solar hardware, geared toward components used in large-scale projects like solar tracker torque tubes. The IRA also includes a 10% tax credit adder for projects that use a certain amount of domestic products — incentivizing developers and installers to buy American.

Within the last year, Nextracker opened three new U.S. factory lines with manufacturing partners. In addition to the Leetsdale location, there are new factories in Phoenix, Arizona, and Sinton, Texas, run by contract manufacturers that also produce other tracker components. Nextracker commissioned new manufacturing lines prior to the IRA passing to address domestic supply chain constraints resulting from the COVID-19 pandemic.

“There was massive congestion at the ports. Rail lines were congested. There weren’t enough trucks or containers. In addition to that, the cost doubled, tripled, even quadrupled for logistics,” said Marco Miller, COO and co-founder of Nextracker. “A lot of companies had to rethink their entire supply chain strategy and Nextracker — although we’ve been manufacturing here — decided to take that initiative to expand our [domestic] manufacturing base to reduce the lead times to get our products to market faster, with more predictability.”

Now with IRA support, the company plans to open more new U.S. factories and expand existing operations. For the last few months, its new factories have produced components that are already being deployed in regional solar projects.

Touring the plant

Bethlehem Steel is one of many factory buildings at the Leetsdale Industrial Park, a 140-acre site flanked by the Ohio River and a commercial railroad line, both of which serve as shipment routes out of Leetsdale. The west end of the Bethlehem building stretches over the river, and military landing craft produced there during World War II were dropped straight into the water before sailing out to the ocean.

BCI previously manufactured components for Nextracker in its other steel facilities; however, the new line in Leetsdale is a factory strictly producing tracker hardware.

“We’ve been working together with Nextracker on supply chain and manufacturing since the start,” Carroll said. “We’ve evolved with them, and this is just the latest evolution.”

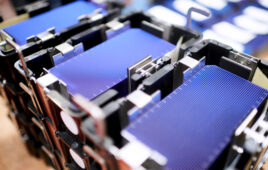

Torque tubes to be used in single-axis solar trackers are fed through a mill. Nextracker

BCI began manufacturing torque tubes at Bethlehem in June following a ribbon-cutting ceremony attended by Nextracker executives and legislators, including Jennifer Granholm, secretary of the U.S. Dept. of Energy. A completed solar tracker stands in the middle of the factory floor with modules autographed by those invited guests. The panels face toward a semi-automated torque tube production line operated by a local workforce.

“These are good-paying jobs, and they’re permanent. Whereas field install jobs are also permanent but they’re not quite as stationary,” Carroll said. “We have second- and third-generation steelworkers whose parents or grandparents worked in these mills.”

BCI’s manufacturing equipment was custom-made for torque tube production. The current manufacturing line was operating in one of BCI’s Malaysian factories before being imported to Pennsylvania.

At one end of the factory floor are rows of steel coils, lengths of flattened metal wrapped into spools. A spool is placed in an uncoiler that feeds the steel sheet into an accumulator and tube mill that makes the metal malleable to bend into the shape of a cylinder. The long edges of the tube are welded together and cut to a length determined by the solar tracker model.

Formed tubes are taken by conveyer belt to the drilling and swaging lines. At the swaging line, torque tube ends are shaped to slide into the next tube to form a tracker row. A gang drill makes holes in the torque tube to attach panel rails and other tracker components. Then, the completed torque tubes are inspected for field use.

When one sheet of steel coil is finished, another is added and welded onto the last to keep the line running, and the cycle repeats.

“We manufacture locally in most of the regions where we actually have projects,” said Yves Figuerola, VP of global sourcing and supply chain at Nextracker. “We’ve been producing in the U.S. for three, four years, but not at a high volume due to, basically, cost. It takes time to set up these facilities.”

Nextracker is opening manufacturing lines to serve immediate regions where there is demand for solar tracker projects, including northern U.S. states where the terrain and weather conditions were not always conducive to single-axis trackers. The company has opened project development in those territories with NX Horizon – XTR, a single-axis tracker system with higher tolerance for undulating land. Completed torque tubes are loaded onto flatbed trucks and taken to regional projects.

“It’s going to the Midwest and Northeast,” Carroll said. “There’s a lot of country that’s a day drive from here, so that’ll be it primarily. There’s enough there for us to stay busy.”

A welder connects two spools of steel coil. Nextracker

The steel processed at the Bethlehem plant is also sourced from local mills, including from United States Steel in Pittsburgh. The steel used in Nextracker torque tubes is produced in electric arc furnaces, which produce considerably less carbon compared to traditional coal-powered blast furnaces. Portions of the steel are sourced from recycled metals, as well.

Nextracker plans to increase output at current facilities and open new factory lines in the United States quickly. Figuerola said the company is finalizing agreements with several other contract manufacturers at the time of publication.

“I was telling people that things are going to grow exponentially, and then looking back, I realized it has been growing exponentially for 20 years,” Figuerola said. “[The IRA] would just be another layer of acceleration, but it has been like this forever in solar. It’s exciting and I think it’s going to unlock an amount of projects that developers were maybe hesitant to try. It’s going to push everything.”

BCI plans to add a second torque tube line to the Bethlehem plant by the end of Spring 2023 and is setting up equipment to produce panel rails as well. The second half of the Bethlehem mill remains undeveloped, and Carroll expects to eventually cover the remainder of the dirt floor with concrete and reopen the large doors over the Ohio River to ship tracker hardware by water.

In the pursuit of a fully domestic solar supply chain, tracker manufacturers have the unique advantage of working with fewer materials necessary for production than other components found on a solar array.

“I would say the steel parts of solar systems in general are easier to make. It just takes longer to build a module plant,” Carroll said. “Not just trackers, but solar racking is going to be probably the first to be made here because we already have the inputs here.”

Tell Us What You Think!